The Plunger Pump BZ18120 is a heavy-duty component engineered for high-pressure washers, built to tackle the most demanding cleaning tasks with unwavering power and durability, making it a top choice for professional and industrial applications.

Ultra-Durable Construction for Extreme Conditions

Constructed with a rugged ductile iron body, the BZ18120 offers exceptional strength and impact resistance, capable of withstanding the rigors of continuous heavy use in harsh environments. Its head is forged from high-grade stainless steel, providing superior corrosion resistance against aggressive cleaning chemicals, saltwater, and industrial pollutants. The internal components, including hardened chrome-plated plungers and heat-resistant ceramic valves, are designed to handle extreme pressure and temperature fluctuations, ensuring a prolonged service life even under the most strenuous operating conditions. This robust build guarantees reliable performance in long-term, high-intensity cleaning operations.

Unmatched Pressure and Flow for Deep, Fast Cleaning

Equipped with a high-capacity piston pump system, the BZ18120 delivers an extraordinary high-pressure output paired with an impressive water flow rate. This powerful combination enables it to effortlessly break down and remove the toughest contaminants, such as thick industrial grease, baked-on oil, heavy rust, and compacted debris from large surfaces. Whether you're cleaning industrial machinery, construction equipment, shipping containers, or large commercial vehicles, this plunger pump provides the brute force needed to achieve a deep, thorough clean in minimal time, significantly boosting operational efficiency.

Advanced Operation and Pressure Management

The BZ18120 features an advanced pressure management system with a precision pressure regulator and a digital display, allowing operators to monitor and adjust pressure levels with pinpoint accuracy. It offers a wide range of pressure settings, from low-pressure rinsing to ultra-high-pressure blasting, making it suitable for a diverse array of cleaning tasks. The ergonomic control panel ensures easy operation, even for extended periods, while the built-in safety features, such as pressure overload protection and thermal shutdown, prevent damage to the pump and ensure operator safety. This level of control and safety makes it ideal for professional operators handling complex cleaning projects.

Specialized Application in Industrial Settings

Designed with industrial needs in mind, the Plunger Pump BZ18120 excels in a variety of heavy-duty applications. It is widely used in manufacturing plants, refineries, construction sites, shipyards, and waste management facilities, where intensive cleaning is required on a regular basis. It's also a key component in professional pressure washing services that handle large-scale projects, such as cleaning bridges, stadiums, and industrial warehouses. Additionally, it can be integrated into custom-built high-pressure cleaning systems for specialized industrial processes, showcasing its adaptability to unique cleaning requirements.

Seamless Integration and Universal Compatibility

Installing the BZ18120 is designed to be straightforward, with a universal mounting design that ensures compatibility with most industrial-grade high-pressure washer systems, including both electric and diesel-powered models. It comes with a comprehensive installation kit, including heavy-duty hoses, fittings, and detailed instructions, allowing for quick and secure integration into existing setups. Whether you're upgrading an aging pump in a large cleaning fleet or building a new industrial cleaning system, the BZ18120 offers a seamless installation experience, minimizing downtime and getting your operations up and running quickly.

Choose the Plunger Pump BZ18120 for your heavy-duty high-pressure washing needs and experience the power, durability, and precision that set it apart. It's a reliable workhorse that will consistently deliver exceptional cleaning results, even in the most challenging industrial environments.

| Model |

Flow |

Pressure |

Power |

Weight |

Speed |

|

| 1/min |

gpm |

bar |

psi |

hp |

kw |

kg |

rpm |

| BZ18120 |

12.8 |

3.39 |

85 |

1232 |

3 |

2.2 |

6.7 |

1450 |

|

| BZ18120 |

12.8 |

3.39 |

95 |

1377 |

3.4 |

2.5 |

6.7 |

1450 |

|

| BZ16120 |

10 |

2.68 |

80 |

1160 |

2.4 |

1.8 |

6.7 |

1450 |

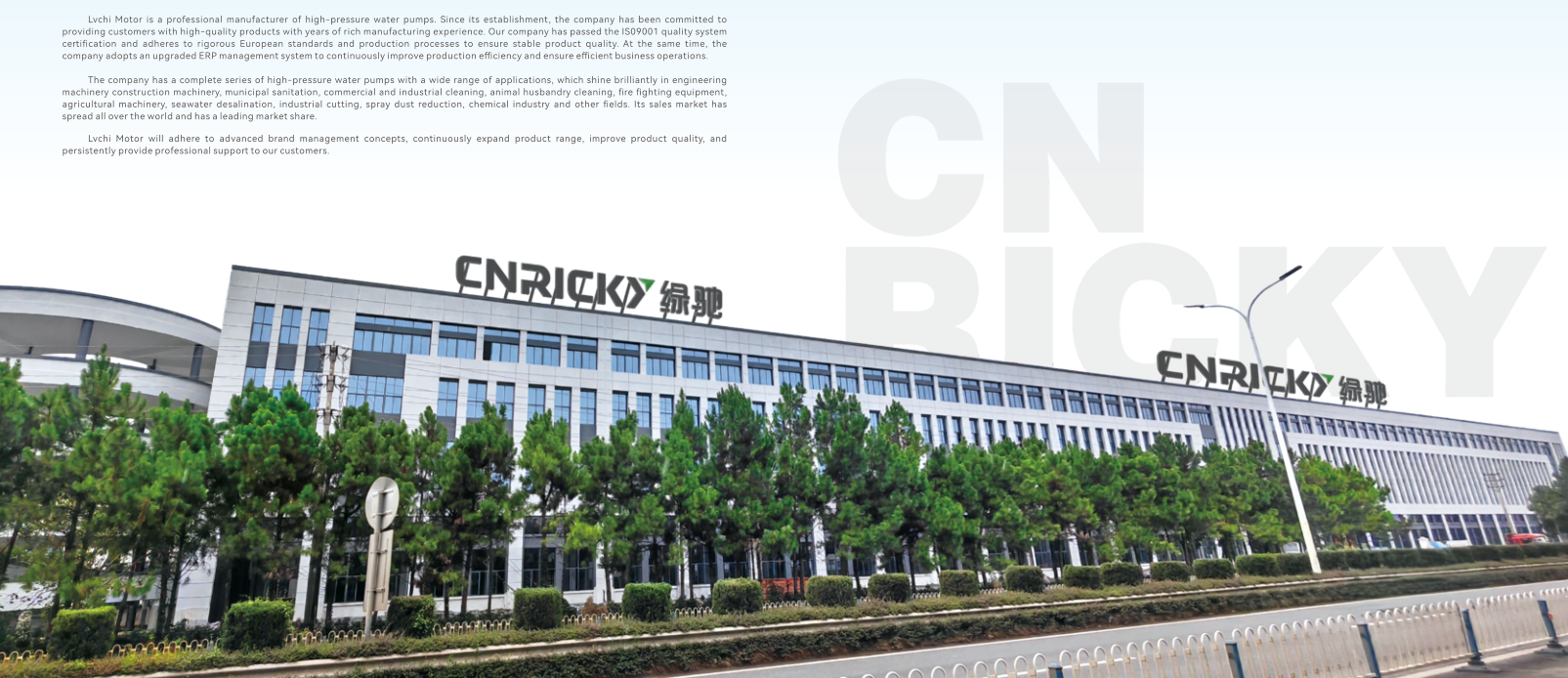

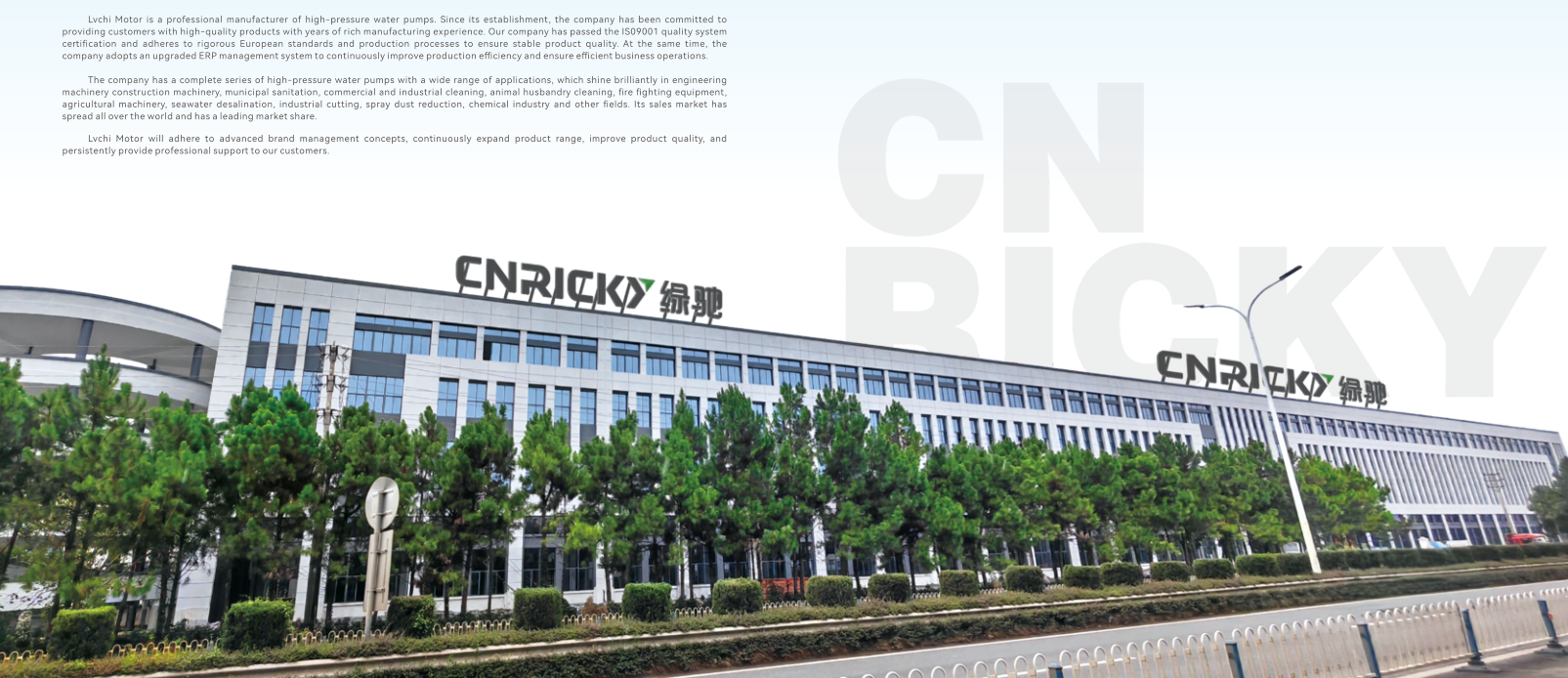

Founded in year 2000, ZHEJIANG LVCHI MOTOR CO.,LTD has been specialized in making high pressure washers, pumps, and accessories for more than 20 years .We have our own manufacturing plant, which covers about 30000 square meters.

As one of the leading manufacturers of high pressure washers in China, our products are sold well in Europe , South America , Middle East , Southeast Asia and so on . And we have gained a good reputation among them .We are dedicated to providing high quality washer to customers with our optimized services . We are looking forward to building up more win-win cooperation with customers around the world.

Q: Do your pumps come with a warranty, and what does it cover?

A: All our high-pressure washer pumps include a 12-month warranty. It covers manufacturing defects, performance failures under normal use, and free replacement of faulty components—ensuring your investment is protected.

Q: Can your pumps work with equipment from other brands without issues?

A: Yes, our pumps are designed with universal compatibility in mind. They fit most standard high-pressure washer models from leading brands, with adaptable interfaces to minimize installation adjustments.

Q: How long does it take to deliver bulk orders, especially for international clients?

A: For bulk orders, production typically takes 15–20 days. International shipping via sea or air averages 30–45 days (depending on the destination), with expedited options available for urgent needs.

Q: Are your pumps certified for use in different global markets (e.g., EU, US)?

A: Absolutely. Our pumps meet CE, UL, and ISO 9001 standards, ensuring compliance with safety and performance regulations in the EU, US, and most international markets—facilitating smooth import and local sales.

Q: What if we need technical help during installation or maintenance?

A: We provide a dedicated technical support team available via phone, email, and video calls. They offer step-by-step installation guides, maintenance tutorials, and real-time troubleshooting to resolve issues quickly.

ONLINE

ONLINE